We all spend a lot of time on social media and we often find ourselves spending hours and hours watching factory videos. The way the machines work, the process of creating an item. Things that we all use in our day to day lives, its fun to dig a little deeper and learn a little more about their history. Wood working is one such industry which everyone enjoys watching and learning about.

Especially in the time of climate change, we’ve some to a point where it doesn’t seem possible reverse the climate change. This has led many people to finally switching to eco-friendly items, from their toothbrush to their home décor, everything wooden! Woodworking is on the rise today and for the better.

At Wittswood all our products are made of 100% sustainable wood. While we pride ourselves for contributing in the sustainable world, it’s a bonus that working in a factory can be de-stressing for us. The woodworking machines and the manufacturing is always so interesting and rather satisfying to engage with.

We are woodworkers based in Lincolnshire and are surrounded by machines every day, all day. We love our job and would not trade it for anything. The way the machines work, carving and crafting a simple log of wood into something creative and innovative makes our hours of hard work worth it in the end.

There are a lot of woodworking machines which contribute in the process. If you’d like, you can have a virtual tour around our factory and explore all the machines and our workplace!

In this article, we would like to give you an insight of our factory and tell you about all the woodworking machines it takes to transform a piece of wood into something innovative.

1. Resaw Machine

A Resaw Machine is one of the most useful machines in a wood factory. It is a cutting wood machine. The Resaw Machine cuts all sawn boards to the correct width. So if you want multiple boards cut to the same size, this machine might be your go-to.

2. Wadkin Moulder

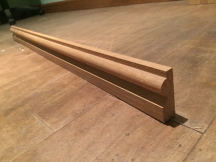

A Timber Moulder is used to machine all the boards to the correct profile. If you are a wood worker or simply take interest in wood working, you would know that there are a lot of wood profiles and styles which are often not easy to carve by hand. In such case, a timber moulder is a great equipment to get just the right profile quickly and easily. Below you can find pictures of our moulded Beading - Scotia and Quadrant.

3. Weinig Optimiser

While working on wooden items, in majority of the cases we primarily need solid planks and panels of the wood to progress the complete product. For this task, your go-to machine is the Optimising Saw which automatically cross cuts the wood. It is time saving, maximises productivity and promises quality of work.

4. Tagliabue Multi-Head Profile Sander

Sanding machines for wood are one of the most important and common equipment at a woodworking site. However, when it comes to stylish and complex profiles, it can be a task to sand them over. That’s why Wittswood uses a multi-head profile sander which does a great job at sanding narrow corners or tight angles of the wooden items. Moreover, while sanding can be time consuming, this machine makes it rather easy and time efficient. Below you can find the picture of our sanded Solid Oak Torus Architrave.

5. Briquette Bagging Machine

Wittswood provides eco hardwood briquettes but bagging the briquettes can be a hectic task, especially when you have various order bespoke products to manufacture and deliver. That’s why, we use a Briquette Bagging Machine which makes the task of bagging briquettes so much easier and quick.

6. Orion Orbital Wrapper

At Wittswood we like to work on unique, custom projects which means we often have the responsibility of safely delivering big and odd-shaped items. It can be difficult to package them well and that’s why we have using fully automatic Shrink Wrapping Machine.

This machine has proven to be one of the most useful and cost effective machines in our workplace. Despite using it for more than a decade, it still works in a perfect condition. Unfortunately, we’re relocating and can’t bring this machine with us. Currently this machine, Orion HRW50A Orbital Wrapper is up for sale on ebay. If you’re looking for a second hand Shrink Wrap Machine in a good condition and at a reasonable price, please reach out to us @ 01205 722700.

If you’d like, have a tour around our factory where you will find all the machines mentioned in this article and more.

Ultimately, we believe that every product determines its own production method and therefore its own set of machines. At Wittswood, we never compromise on the machines or the requirements of the product and thus, we are able to offer quality in our work. All our products are made to measure with 100% Solid Oak. We use some of the most advanced and high-tech machines at our workplace to produce strong yet stylish custom items for our clients. If taken care of well enough, our products can last a lifetime.

Some of our most popular products are Ledge and Brace Doors. If you’d like to know more about Ledge and Brace doors, head to our blog - Types of popular and durable Ledge and Brace Doors - AVAILABLE NOW!!

If you’re thinking about switching to wooden floors, don’t miss our blog - An Honest Guide to Wood Floor Installation!

Have any queries? Need advice? Want to place an order? Please reach out to us @ 01205 722 700!